It defines the Investment Priority Areas of Iligan City and Lanao del Norte; Profiles of Priority Investment Areas; and existing Investment Incentive Programs for MSMEs.

CONTENTS:

Province of Lanao del Norte

1. INTRODUCTION

a. Scope of the Industry/Industry Definition

Seaweeds as initially intended for consumption, are now being used gradually as input for production among industries and for export thus, generating income for fisherfolks and coastal communities. Among the over 20 species of green, brown, and red seaweed species, the edible specie are called sea vegetables. Sea vegetables are rich in protein, carbohydrates, iodine, vitamins A, B and C and other elements. Sea vegetables are eaten as viand (meat, fish stews), dessert, salad, and soup, among other preparations.

Seaweeds can be classified into three broad groups based on pigmentation: brown, red and green. Botanists refer to these broad groups as Phaeophyceae, Rhodophyceae and Chlorophyceae, respectively. Brown seaweeds are usually large, and range from the giant kelp that is often 20 m long, to thick, leather-like seaweeds from 2-4 m long, to smaller species 30-60 cm long. Red seaweeds are usually smaller, generally ranging from a few centimetres to about a metre in length; however, red seaweeds are not always red: they are sometimes purple, even brownish red, but they are still classified by botanists as Rhodophyceae because of other characteristics. Green seaweeds are also small, with a similar size range to the red seaweeds.

The seaweed industry provides a wide variety of products that have an estimated total annual value of US$ 5.5-6 billion. Food products for human consumption contribute about US$ 5 billion of this. Substances that are extracted from seaweeds - hydrocolloids - account for a large part of the remaining billion dollars, while smaller, miscellaneous uses, such as fertilizers and animal feed additives, make up the rest. The industry uses 7.5-8 million ton of wet seaweed annually. This is harvested either from naturally growing (wild) seaweed or from cultivated (farmed) crops. The farming of seaweed has expanded rapidly as demand has outstripped the supply available from natural resources. Commercial harvesting occurs in about 35 countries, spread between the Northern and Southern Hemispheres, in waters ranging from cold, through temperate, to tropical.

The Philippines is the second biggest producer of seaweeds next to China . Philippines is the leading supplier of Euchema Seaweeds accounting for about 80% of the total world supply .Seaweeds is largely cultured in Mindanao accounting for about 77 % and of total output in 2000. The autonomous Region of Muslim Mindanao particularly Tawi-tawi and Sulu accounted for 53% of the total output followed by Southern Tagalog ( 23%), and Western Mindanao ( 17%).

The development of seaweeds industry in the Philippines can be traced back in 1967, the first commercial farming trial for Euchema was developed at Caluyas Island in Antique which is south of Mindoro. The method used was nylon line with bamboo floats in an area of 2,500 sq. meter. The Marine Colloids provided a seed fund of P 45,000 to initiate the project.

After the experiment in Caluyas, the farming trails were transferred to Ilin, Mindoro in 1969. At Ilin, Mindoro, Mr. Alvarez trained a Musim teacher,Mr. Baltapa Anjail from Siasi, sulu, for a couple of months. After his training, developed a seaweeds farm with the assistance of Mr. Alvarez at Tapaan Island, Siasi, which is a 25 has. Lagoon. This farm turned out to be a very beautiful farm of consisting of a mixture of Euchema species.

In 1971, the project was then shifted to Sitangkai wherein the system was changed from company farm to family farm. A $25,000 grant was provided for the development of family farm system which was worked out with the municipality of Tawi-Tawi thru the local officials.

In 1973, Euchema Seaweed Farming Training Course was held in Zamboanga City sponsored by Marine Colloids (Phils.) Inc., UPNSDB, Bureau of Fisheries and Aquatic Resources, etc. It was attended by some 13 representatives from Luzon, Visayas and Mindanao. In June of 1973, the first commercial Euchema seaweed farming was established in Danajon Reef between Bohol ad Leyte. It was funded by Genu Products ( Phils) Inc.

The processing of seaweeds is mostly done in Cebu, where a good number of processing plants are located. Other processors, which also serve as seaweed buying stations, are found in Mindanao; one is in Region 8.

Local consolidators are found in Lanao del Norte namely, the Baroy Marine Product, an exporter for Cargill, France, DRJ Seaweeds Trading and Farming, and Kolambugan Cooperative are indirect seaweeds traders and base in Kolambugan, Lanao del Norte.

b. Localized Cluster Map

Seaweeds are found in the municipalities of Tubod and Kolambugan of the Province of Lanao del Norte.

Map of Lanao del Norte

Map of Lanao del Norte

Kolambugan is a 4th class municipality in the province of Lanao del Norte, Philippines. According to the 2007 census, it has a population of 25,306 people.

The Municipality of Kolambugan is accessibly located along the Panguil Bay area facing Ozamiz City in the Province of Misamis Occidental, 47 kilometers west of the capital town of Tubod. It is centrally located northwest of the Province. The Municipality of Kolambugan is bounded by the Panguil Bay on the North, Municipality of Tangcal and Magsaysay on the South; the Municipality of Maigo on the East; the Municipality of Tubod on the West.

In seaweed cluster covers the two municipalities of Kolambugan and Tubod . Four (4) barangays of Kolambugan namely ; Simbuco, Manga, Tabigue, and Mukas and Tanguengueron/Lamalama for Tubod, Lanao del Norte are into intensive farming.

To date, there are about 1,000 families/growers spread around the five barangays with production capacity of 12,000 monolines utilized by farmers. Total area planted approximately between 200-300 hectares and an annual production of 3,000-4,000 metric tons.

c. Products and Linkages

• Aside from being consumed as food, seaweed is utilized as a raw material in the manufacture of industrial products such as alginate, agar, and carrageenan. Among the five ( 5) species of seaweeds namely, Caulerpa, sargassum, gelidiella, gracilaria and Euchema, the later is usually exported as raw material.

• Euchema has a number of uses and enjoys the heaviest demand in the market, both local and international. Modern processing techniques transformed seaweed into power called “ carrageenan”. More specifically, the various end-users may be classified under two categories “food” and “non-food”. “Food” accounts for more than 70% of the world demand of the product.

• For non-food application, seaweed is either utilized as fertilizer or for extraction of industrial gums and chemicals.

The major export buyer of Lanao del Norte is the Cargill Tecturizing Solutions. Cargill Texturizing Solutions is one of the leading producers of hydrocolloids, emulsifiers, lecithins, cultures, starches, soy flour and functional systems worldwide.

With plants located all over the world, Cargill Texturizing Solutions is a recognized, long-time partner of the food industry. Production facilities are state of the art and guarantee exact reproducibility of products and their components.

The company manufacturers refined seaweeds as raw materials for food products. The seaweeds purchased from various sources are refined and processed into stabilizers and as input of production for the following uses: (1) as binder, moisture holder, and gelling agent that have been acclaimed by food processors all over the world, (2) raw materials for : ice cream to prevent whey separation, lotions and creams for slip and improved rub-out sensation, shampoos for foam stability, milk stabilizer, medicine capsules, toothpaste as binder, stabilizes hams, sausages and other meat products for toothpaste as binder and for dairy applications, (3) provide high gel strength for processed meat and fish , (4) Canned food for water and fat retention and binder, (5) dessert applications as home-made flans, custard and bakery creams, water gel desserts, glazing, frozen desserts and powdered mixes .

In the Province of Lanao del Norte, dried seaweeds are directly sold to export and local buyers. Export market is Cargill, France and local buyers are located in Cebu, Zamboanga, and Manila. Major buyers are : (1) PCI Worldwide in Manila, (2) VW Marines in Zamboanga, (3) Genu, Phils, Cebu City ,(4) and Shemberg, Phils., Cebu City .

d) Number and Size of firms/growth of firms

Seaweeds industry started in Lanao del Norte in the 80s. A handful growers and areas were utilized.Traders from Zamboanga and Cebu City will occasionally come and purchased the goods in bulk. When the coconut industry slowed down in the 1990, farmers were forced to go down and joined seaweeds farmers in opening new areas for cultivation. As the number of growers grew in size, local consolidators started establishing their buying stations and directly sold dried seaweeds in Cebu and Zamboanga City. Seeing the potential growth of the industry as more people where engaged into seaweed farming in the early part of 2000, the LGU,national government agencies and multi donors started to support the industry. Solar dryers, seedlings and financial assistance have been provided to support the growing business. Philippine Carageenan Processing Plant was established in Baroy, Lanao del Norte in 2003 with the initial investment of P95M. The plant ceased operation in 2005 during the La Niña and El Niño phenomenon and the outbreak of ice-ice diseases. Operational capital provided by consolidators to the farmers were totally lost.

The industry slowly gained momentum in the early part of 2006 and farmers again cultivated their areas and financial support from local government, national agencies and consolidators flowed back in the operation. In 2006, seaweeds total production hit around 3,500 metric tons and gradually increased production up to this time.

At present, a total of one (1) exporter, three (3) indirect exporters and small unlicensed consolidators are conducting seaweeds trading business in the area. Baroy Marine Products is categorized as small industry the rests, are micro.

e) Key players in the sector

The following are the major key players in the seaweed industry of the Province of Lanao del Norte :

Growers :

Major Organizations:

Kolambugan Seaweed Growers Association (KOSGA) with 457 members

Tangueguiron Guso Growers Association(TAGGUSA) with 200 Members

Manga Fishermen Multi Purpose Coop. (MAFIMCO) with 350 members

Simbuco Aqua Marine Multi Purpose Coop. with 109 members

Nagmata Manggusoay Sa Tabigue with 53 members

Consolidators :

Baroy Marine Products – exporter to Cargill, France

DRJ Seaweeds Trading and Farming – indirect exporter

Kolambugan MPC – indirect exporter

Two (2) small consolidators

2. SECTORAL PERFORMANCE/RESOURCE ASSESSMENT

2.1 Sectoral Performance

2.1.1 Historical data on Gross Value-Added

Volume of production in Lanao del Norte area totaling around 3,000-4,000 metric tons with the months of October, November and December as lean months . Increase in average annual per capita income of growers from P 35T in 2001 to P 180T in 2007 and increase in average volume of production from 1480MT in 2001 to 4,000 MT in the current year.

Total membership of the existing seaweeds groups increase by 10% from 457 in 2001 to 503 in the current year for KOSGA, and TAGGUSA of 15% from 200 to 230 members of the current year.

Increase in asset size is also observed among growers. The asset size of KOSGA have increase from P 300,000 to P 5,400,000 or 1,800%. TAGGUSA on other hand, registered a total asset size from P 33,000 in 2001 to P 1,260,000 as of 2007 or a total increase of 3818%.

2.1.2 Investment Performance, Employment Data

The support provided by various sector to the seaweeds industry in 2000 was more of experimental than commercial business. Bureau of Fisheries and Aquatic Resources ( BFAR) started conducting trainings, and provided technical and financial support to growers. The Growth in Equity in Mindanao, LGU and other funding donors have provided several assistance in a form of dryers, seedlings, technology enhancement and working capital to develop the industry. Estimated investments as follows : Growth Equity in Mindanao amounted to P 5M, LGU/LGSP P400T, Quendancor (loan) P 1.34M, One TPM ( Congressional Fund) P.5M, STARCM 1.2 M, Peace and Equity in Mindanao P 150T, seedlings and technical support from BFAR and cash advances made to farmers by consolidators amounted to P 5M.

When the industry started in the 1980 there were around 15 farmers and increased to 500 in 1990 have ballooned in numbers to more than 1000 farmers at present.

2.1.3 Historical data on market performance: Domestic and Exports

In the 1980 production level of seaweeds in the Province of Lanao del Norte was minimal and registered only between 2-3 metric tons for maximum of three (3) months operation per year. In the 1990, farmers gradually increased in numbers and cultivated around 11 hectares and produced 5-7 metric tons per harvest season. As the demand grew both in local and international, more assistance poured in the industry. As a result, a bigger leap in production volume from 7 metric tons per cropping to 100 metric tons in early part of 2000, and steadily increased to 150 metric tons in 2004. With the El Niño and La Niña phenomenon in 2005, only 50 metric tons were recorded sales for the year. In 2006 and at present, total production is between 170- 200 metric tons per harvest season.

Baroy Marine Products is the only exporter of seaweeds in Lanao del Norte. A trial order of 40 metric tons have been delivered to Cargill, France in 2007 and 80 metric tons in the first quarter of 2008 with an export sales amounted to $143,000. Lack of capital to finance the volume requirements of Cargill, France hindered Baroy Marine Products to meet deliveries on time.

2.1.4 World and National Production data

Seaweed processing in the Philippines was recognized as an industry in 1966 when the unprecedented commercial exploitation of the then widely growing Eucheuma seaweed boosted the country’s export with the record of 800 metric tons.

In 1972, Tawi-tawi and Zamboanga fishermen started the first seaweed commercial farms in the country. Since then, the industry has grown and is considered one of the major export aquatic commodities of the Philippines.

By 1980, several firms in the Philippines were manufacturing a new grade of carrageenan from seaweed of the Eucheuma variety. This new grade of carageenan had found markets all over the world and was known as semi-refined carrageenan (SRC) or Philippines National Grade (PNG) carrageenan.

In 1988, the Philippines ranked as the 3rd leading producer of seaweed all over the world.

Blessed with the right climate and oceanographic conditions, the Philippines’ southeast seas are the world’s major sources of cultivated Eucheuma – the seaweed with carrageenan yield. At present, the country accounts for 80% of the total world supply.

It is significant to note that about 73% of total Philippine production of seaweed comes from the island of Mindanao. Most of the products from Mindanao are in the form of dried raw seaweed.

Europe is the number one in terms of volume share per country of Philippine’s total export of dried seaweed.

The Phils. is the 2nd biggest producer of seaweeds next to China . Phils is the leading supplier of Euchema Seaweeds accounting for about 80% of the total world supply .Seaweeds is largely cultured in Mindanao accounting for about 77 % and of total output in 2000. The autonomous Region of Muslim Mindanao particularly Tawi-tawi and Sulu accounted for 53% of the total output followed by Southern Tagalog ( 23%), and Western Mindanao ( 17%).

For the past ten years, the Phils. Seaweed production increased at an average rate of 9.4% annually from 284,000 tons ( Php 1B) in 1991 to 618,000 tons ( Php 1.9B ) in 2000. It is estimated that 200,000 families are directly dependent on seaweed culture. Top Philippine seaweeds export destinations include France, UK, Ireland, Denmark, USA, and Germany .

In 2000, the export value of the seaweeds industry is estimated to reach US$130 million. Seaweeds. Seaweeds rank third in foreign exchange earnings of the Philippines.

The overwhelming success of the sea farming of Eucheuma and Kappaphycus has been experienced in the country. In Mindanao more specifically in Tawitawi, Jolo, Basilan, Zamboanga and Lanao del Norte accounts for 70 percent of the country’s total Eucheuma and Kappaphycus production, the balance were produced by Central Visayas and Southern Tagalog.

The Philippines ranks third behind China and Japan in the international production and export of dried seaweeds, mostly Eucheuma and Kappaphycus. For some time now, it has been the world’s number one exporter of Carrageenan, a versatile hydrocolloidal substance extracted from Carrageenophytic red seaweeds like Eucheuma and Kappaphycus or Guso’ (Bisayan). Seaweed also ranks third among fishery export commodities in the Philippines, behind prawns and tuna.

Slowdown

There is a slowdown of operation in year 2007, the Shemberg group that used to process 40 tons of carrageenan daily valued at about $350,000 has dropped to 10 metric tons following the shortage of raw seaweed.

During a good harvest, sales could even reach $400,000 daily for Shemberg but the later part of 2007, the company is now doing $85,500 a day. Shemberg had to shut down its facilities for at least 10 days in February due to lack of raw seaweed.

While the Philippines could get raw seaweed from Chile and Canada, the seaweed production in these two countries could not fill the shortfall in the production of the Asian countries.

On top of the production shortfall, the seaweed processors also had to contend with the rising prices of seaweed.

Philippine seaweed, eucheuma cottonii, was sold at $800 per metric ton in 2007 but the price has gone up to $1,600.

Even Indonesia cottonii now commands a higher price, from $600 per metric ton in 2007 to $1,400 this year.

2.1.5 Regional Data

Mindanao accounts for 71% of the seaweeds production of the entire Philippines. It was estimated in 1996, that some 100,000 families are engaged in seaweeds farming and about 72% of these families are located in Mindanao particularly in the ARMM provinces and the Zamboanga Peninsula.

Zamboanga City has more that 2,000 hectares devoted to the seaweeds farming providing livelihood to more that 3,000 families. At present, there are three processing plants in Zamboanga City producing semi-refine carrageenan and alkali treated chips. Another processing plant will operate in year 2001 also to produce semi-refined carrageenan. Presently processed and dried seaweeds are exported to numerous international markets, shipped to Cebu or Manila in the dried form for further processing into carrageenan.

In the Province of Lanao del Norte , the seaweeds industry hit thousand of pesos in terms of sales in 1990s and registered an average growth of 60% for the period 2000-2004 from 60 metric tons to 100 metric tons. The rather disappointing performance in 2005 was the effect of El Niño phenomenon that hit the production areas resulting in the drop in production from 100 metric tons in last quarter of 2004 to 50 metric tons harvested in the early part of the year. This production loss and the loss in value of the peso owing to the Asean financial crisis were responsible for the decrease in the value of seaweeds. The industry however, started to pick up and registered remarkable performance in the mid of 2006 up to the present.

2.1.6 Productivity Levels

Productivity level among seaweeds growers in the Province of Lanao del Norte have greatly improved with the assistance of the BFAR who provided farmers the trainings and technology enhancement in seaweeds culture. However, there are various factors contributing to the low productivity of seaweeds in the area;

1. Production per unit of raft not maximize and seedling not intensively applied.

This contributed to the low productivity levels i.e., the distances between lines and cuttings attached to monolines are closer. The size of the raft depends on the length of the frame materials. Aside from maximizing the number of plants on a raft, it has been observed that the adverse effects of more intense sunlight near the surface of the water column is offset by the slightly crowded spacing of the plants.

2. Seaweeds farming is also affected with the seasonal changes in the ecological factors such as light intensity and water temperature regimes, nutrients and weather disturbances. These factors seem to be the predisposing conditions which result in the reduction or the complete loss of crops. Among these problems are “aging effect”, negative growth rates, the ice-ice disease, weeds and epiphytes, grazing, and crop loss due to typhoon. The outbreak of the ice-ice disease greatly damaged the crop in 2005. At present there is no known method in controlling the occurrence of ice-ice. To minimize loses, the farmers harvested the crop as soon as the disease appears or cut the portion affected by the disease and continue the culturing period. When harvested, a new batch of healthy plants is again used as starter seedstock.

3. Other factors attributed the lower seaweed production is the increased temperature of seawater. The ideal temperature for seaweed is below 26 degrees Celsius but the temperature at the seaweed farms has gone above 26 degrees. Due to these reasons, the seaweed production has declined by as much as 50 percent in some areas in the Panguil Bay. The decline in the seaweed production in 2005 has affected farmers more. A seaweed farmers used to earn at least P20,000 per harvest but, with the decline in seaweed production, their income could not go beyond P6,000. Seaweed farmers usually enjoy good harvest from January to June, which are considered peak months for seaweed farming. The difficulty to access financing as the biggest factor in the lower seaweed

2.2 Price Information

Comparative Price Levels (Province versus major production centers)

The comparative price levels of seaweeds are shown below as of June, 2008;

Companies- Buyers of Seaweeds

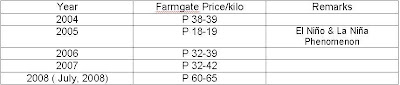

Farmgate Price (at least 5 years)

Farmgate price of seaweeds for the past 5 years starting year 2004 up to July, 2008;

Source : Baroy Marine Products

Source : Baroy Marine Products

Retail Price (at least 5 years)

Retail price of seaweeds in the past 5 years as follows;

Source : Baroy Marine Products

Source : Baroy Marine Products

2.3 Financial Information

Updated Cost of Production

The cost to produce seaweed on monoline basis are as follows: 100 kilos planting materials at P 1,200, ½ roll monoline at P800/roll, 25 pieces pet bottles at P 2.00 per bottle, 1 big roll soft tie at P 130 and labor cost (variable) . Estimated total production cost amounted to P 2,000 monoline. Total average yield of one (1) monoline is 50 kilos dried seaweeds harvested after 75 days.

The component of cost to sell for local market are: farm gate price per kilo, freight cost ( land and sea) , commission/brokers fee, sack, labor cost for packing/ redrying. As of July, 2008 estimated cost to sell is between P 70-75 per kilo for local market and $ 1,500 - $ 2,000 per ton for export market.

2.4 Transport/Freight Cost

For local deliveries, all product will pass through the port of Kolambugan, Lanao del Norte via sea transportation to the port of Ozamis City. Trucking cost from warehouse to the port of Kolambugan amounted to P 35 per sack ( with average capacity of 90 kilos). All products will be loaded in the sea vessel ( Daima Shipping Company) to the port of Ozamis City with a freight charge of P59-70 per sack. Freight cost from Ozamis to Cebu City shall be borne by the buyer.

For export market, same procedure will be followed except that when the goods will arrive at Cebu City, a broker will take care of the delivery of the goods from Cebu City to any foreign destinations. Broker’s fee is dependent on the volume of deliveries normally between P 500-P 1,000 per metric ton.

2.5 Profitability Ratios/Industry Standard

For growers, a profit percentage/ratio between 20-30% can be realized per planting season and for traders/consolidators, an industry standard profitability ratio between 25-35% is realized.

3. INVESTMENT OPPORTUNITIES/SUBCONTRACTING OPPORTUNITIES PER SECTOR

Providing inputs of production such as planting materials , soft tie, pet bottles, and supplier of labor can be an avenue for subcontracting arrangements.

Providing planting materials to growers places an important part in the growth of the industry. It is a common dilemma among growers that planting materials out of the harvestable seaweeds will not produce good harvest as the volume of production is dependent on the quality of planting materials used. It is most unlikely to get a seedling out of harvestable seaweeds during the rainy season when flooding is frequent. This will contaminate the seaweed and not suitable as seed stocks.

The term “planting materials or seeds” here refers to both the vegetative propagules (cuttings) and spores which can be utilized as planting materials. The importance of the availability of local as source of seed materials should always be emphasized. These seed stocks may come from natural stocks or those from cultivation and maybe done with other subcontracting units. The establishment of a nursery or seed bank will be a good business opportunities on this sector.

4. COMPARATIVE/COMPETITIVE ADVANTAGE

4.1 Natural Resource Endowments

The Municipalities of Kolambugan and Tubod are conveniently located along the Panguil Bay area facing Ozamiz City in the Province of Misamis Occidental. The Municipality of Kolambugan is 47 kilometers West of the capital town of Tubod. Both areas are equidistant from each other and located Northwest of the Province.

The Panguil Bay area is located at the south of Tangub City, on the boundaries of Misamis Occidental, Zamboanga del Sur and Lanao del Norte Provinces, western part . Total number of hectares for seaweeds cultivation is 19,500 hectares and only 15% are utilized with an altitude at sea level.

The area is a shallow sea bay at the head of Iligan Bay, with extensive intertidal mudflats and mangrove swamps. Humid tropical climate with the rainfall more or less evenly distributed throughout the year (Type IV).

Just like Zamboanga, Tawi-Tawi, Jolo and Basilan, the Province of Lanao del Norte is endowed with rich marine culture and a stretched of sea waters intended for sea farming . An estimated total number of area planted with seaweeds is more or less between 200-300 hectares.

The key players of the industry are more than 500 growers from the three (3) municipalities of Lanao Norte namely; Kolambugan , Tubod and Maigo.

4.2 Good infra/availability of support services

Billions of pesos was set aside for the various poverty-alleviation and infrastructure projects in Lanao del Norte under the President's Priority Programs and the Office of Development Assistance (ODA) in 2003. ODA and President’s Social Fund ( PSF) projects amounted to millions of pesos was spent on various infra projects and were completed and on-going from 2001-up to the present.

These projects include road and bridge construction, irrigation system, feeder port development, environment preservation and water supply improvement, public markets and post-harvest facilities.

Roads and bridges from Cagayan de Oro to Zamboanga City are more or less 70% concreted and in-land transportation are available at 24/7. For Kolambugan/Tubod Ozamis City route, the Daima Shipping Company provides the means of sea water transportation from 4:00am to 10:00 pm daily. Four shipping companies such as Cebu Ferries, Sulpicio, Gothong, Trans Asia and Negros Navigation are serving the people from Ozamis to Cebu City/Iloilo City. Cebu Star Shipping Line will sail once a week from Tubod, Lanao del Norte to Cebu City.

4.3 Availability of skilled manpower

Labor/manpower resource on seaweeds cultivation and farming are available in the locality throughout the year and paid between P150-200 per day exclusive of meal allowances.

4.4 Reasonable utility rates (rental cost, labor cost, power cost etc.)

At present, labor cost fall below the minimum but, workers are provided with meals and transportation allowances by the consolidators/entrepreneurs. Majority of the tools, equipment and dryers are owned by the entrepreneurs/cooperatives hence, rental cost component is minimized. Power rate in Iligan City is P5.33 per kilowatt hour and P7.55 in Lanao del Norte. Solar drying of seaweed is a common industry practiced and only household power consumption is needed. The use of cell phones are rampant in the area as local land line connectivity is not working well.

5. POLICIES AFFECTING THE SECTOR

The seaweed farming is an OTOP project of the municipality of Kolambugan, Lanao del Norte and became the major livelihood activity of the people substituting the declining income productivity of coconut industry.

The 200-300 hectares planted with seaweeds have been supervised and cleared by BFAR to ensure that the development will not run conflict with the laws being observed and implemented.

Supervision and technical support from BFAR and other government agencies are also provided as part of the joint inter agency collaboration to develop the OTOP project in the area.

6. TECHNO INFORMATION/SOURCES

Sources of technology information comes from various sources namely:

a) Bureau of Fisheries and Aquatic Resources ( BFAR)

Techno transfer/trainings, seedlings ,solar dryers and continuous consultancy activities are being done by the agency .

b) Organization and Local Partners

There are five (5) associations/cooperatives and one development council in Lanao del Norte that are assisting the development of seaweeds and a source of technology information. The following government agencies and private sector groups were organized into a task force known as the Lanao del Norte Seaweed Industry Inter-Agency Task Force with the composition of the following agencies ;

National Agencies

1. Department of Trade and Industry

2. Department of Science and Technology

3. Department of Agriculture

4. Department of Environment and Natural resources

5. Bureau of Fisheries and Aquatic Resources

c) Local Government

d) Office of the Municipal Agriculturist

e) Private Sector/Academe/Multi Donors

1. MSU-IIT

2. Growth With Equity in Mindanao

f) Financial Institution/Congressional Fund

1. Quedancor

Provided loan assistance to Kolambugan Seaweeds Growers Association amounted to P 1.34M and Tanguegueron Guso Growers Association amounted to P 630,000.

2. Countrywide Development Fund of Congressman Badelles (One TPM)

The CDF ( ITPM) Project of Congressman Badelles provided a loan assistance to

the growers ( TAGGUSA and Simbuco) amounted to P 300,000

3.NAFCI

Provided the growers a loan assistance in the amount of P 162,000.

4. Growth With Equity In Mindanao and other funding donors

Assistance provided are solar dryers and cash assistance to MAFIMCO. The following recipient of the solar dryers are as follows ;

Beneficiary Facility Location Funding Agency

KOSGA Solar Dryer Mukas LGSP

Solar Dryer Mukas USAID-GEM

Solar Dryer Manga DA

Solar Dryer Manga USAID-GEM

Solar Dryer Tabigue DA

Solar Dryer Tabigue USAID-GEM

Solar Dryer Simbuco USAID-GEM

Warehouse Manga USAID-GEM

TAGGUSA Solar Dryer Tangueguiron USAID-GEM

7. PROSPECTS & OPPORTUNITIES

After the industry have already moved forward through R&D efforts, processing of seaweeds via value adding say, production of consumer products to meet the country’s food, medicine, and fertilizer requirements rather than ‘totally’ exporting processed and unprocessed seaweeds must also be considered. Appropriate technologies be taught and learned through the various sources of assistance within and outside of the

8. CHALLENGES/ GAPS

8.1 Seaweed Industry Cluster Map

The major factors in the development of the seaweed industry in the

Buyers refer to as the existing entities or individual that procure the goods and services of the growers. DRJ Seaweeds Trading and Farming, Kolambugan MPC and Baroy Marine Products are identified buyers of the product. The dried seaweeds are sold directly to exporters in Cebu, Zamboanga,

Production of seaweeds are supported by inputs of production such as seedlings, drying and packing facilities to produce a quality dried seaweeds. Support entities are provider of capital, supplier of various inputs of production such as; pet bottles used as “floats”, sacks, ropes, and bamboo poles/sticks.

To ascertain success and sustainability of the industry, government agencies such as DTI, BFAR, LGU, DENR and multi donors provided financial and technical support.

As seaweed industry develops, issues and concerns are met in almost all level of production. These identified gaps/issues/problems are taken into real perspective to address these issues to avoid possible recurrence in the future.

8.2 Gaps

The presence of the seaweed industry in the

SEAWEED INDUSTRY CLUSTER MAP

9. ACTION PLAN

The following gaps with corresponding interventions are gathered from the Strategic Planning Workshop conducted by Department of Trade and Industry in the 1st quarter of 2008;